Extensive Inventory of Butterfly Valves and Valve Products

BVC offers a wide range of products, superior support, and service to distributors, resellers, and OEM’S. Our high-performance butterfly valves are designed to perform with excellence in several applications and industries.

Butterfly Valve Types

As a US distribution leader and longstanding supplier of the highest quality butterfly valves, we offer many solutions to choose from. Our top products are highlighted below.

This low maintenance industrial valve is mainly used for shipbuilding, but also for HVAC, petrochemical, fire control, seawater, flue gas, and desulphurization. The Resilient Seated Butterfly Valve seat comes in various forms: EPDM, White EPDM, Buna N, Viton, Viton for Steam, Silicone, and Neoprene. Sizes range from 1.5” -72.0”. Depending on the model, the RSBV can withstand temperatures from -4°F-400°F and a pressure range of 87 psig-250 psig.

Teflon Seated Butterfly Valve design is accurately machined to offer a long service life and low operating torque. It features a cartridge type seat (PTFO over rubber) thus suitable for high cycles. The Teflon Butterfly Seated Valve comes in two versions with a size range of 1.5” -24.0”. Respectively, each can handle pressures of 150 psig or 230 psig, and temperatures of -4°F-400°F. Its applications are OEM, HVAC, fire control, seawater, food service, petrochemical, flue gas, chemical, and many more.

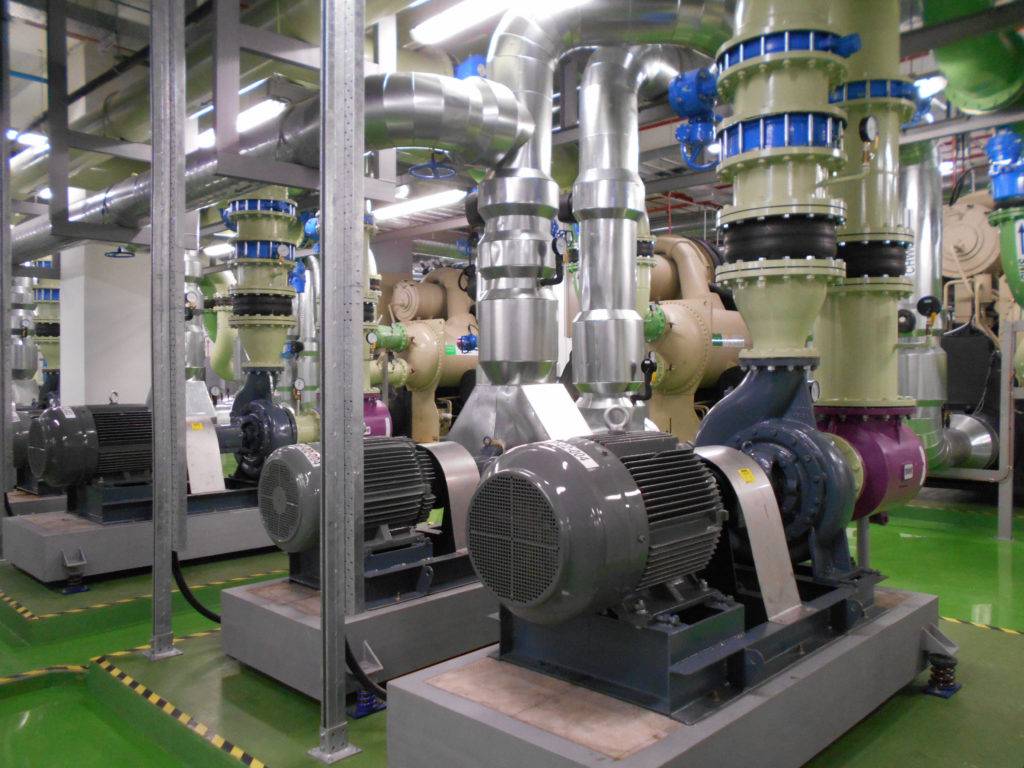

The AWWA (American Water Works Association) Valve is a high-performance class water control valve used extensively in industrial and power plant operations. It improves upon other AWWA valves as it’s easily replaced. The seating is a one-piece steel ring encapsulated in rubber. The sizes range is 14”–104”. It’s built for temperatures between -20℃–120℃ and qualifies for AWWA Pressure Classes 25B, 75B & 150B.

A Pneumatic Valve Actuator performs in harsh environments with its many attributes: waterproof, weatherproof, extreme temperature tolerance, and corrosion resistance. Pneumatic Valve Actuators are well suited for general oil and gas operations such as offshore drilling and oil rigs but they also work for food and drug production. The sizing range 214 in/lbs-81,000 in/lbs. They withstand pressure between 40-150 psig and a wide temperature tolerance range of -30℉~300℉.

High-Performance Butterfly Valves are designed for continuous exposure to extreme conditions. Our Double Offset Butterfly Valve is specially-designed with a reinforced shaft strength and blowout protection. It features a bi-directional shut-off and a seat made of Stellite or reinforced Teflon for resilience to pressure and high temperatures. Such applications for this valve are oil and gas (chemical, petrochemical, and offshore), pulp and paper, HVAC, shipbuilding, power generation, and more. Sizes range from 2”-48”. It has a broad heat tolerance range of -21℉-932℉ and an ANSI pressure rating of either 150 or 300.

The Triple Offset Butterfly Valve is also a bi-directional high-Performance Butterfly Valve. It features a laminated multilayer seat made with Stellite and graphite. The most notable attributes are seat-in-the-body, fire-safe rating, and bubble-tightness. These are manufactured for the most extreme application environments and are found in high-pressure steam operations as well as oil, gas, and chemical operations. The heat tolerance is extensive ranging from -320℉-1022℉. ANSI pressure ratings are 150, 300, 600, or 900.

Butterfly Valve Applications

Butterfly Valves are used for controlling the flow process in a variety of applications. What type of valve is most appropriate depends on the conditions of the application.

Shut Off Valves

Butterfly Valves are a general-purpose shut off valve. They are lighter in weight than other kinds of valves with a tighter seal than a globe valve. This is needed for such applications as water theme parks, food processing, wastewater, or water treatment.

Shipbuilding

Butterfly Valves are often used in ships and shipbuilding because of their ability to withstand saltwater, fit in tight spaces, and operate underwater pneumatically. They are involved with mechanics such as “jacking up” rigs. Some ship operations require a Triple Offset Butterfly Valve qualifies as a Fire Safe approved valve which is needed for some ship applications.

Refineries

Refineries have a complex operational structure. Butterfly Valves integrate well into these various operations. HPBFV and TOV Butterfly Valves have the requisite temperature and pressure tolerances at a fraction of the cost of a ball and gate valve. Examples of refinery applications are offshore rigs, chemical processing, etc.

Custom Butterfly Valve Assemblies

Butterfly Valves are designed for an accurate fit, so we offer custom assemblies. Customized assemblies are offered in sizes up 48″ in pneumatic, electric (single or 3-phase), and electro-hydraulic variations. Off-the-shelf assemblies are ready in one day. Contact us today about your custom Butterfly Valve assembly needs.