27 Apr What is An Electrical Actuator and How Does it Work?

There are two types of actuators: linear and rotary. For mechanics that require a forward-backward movement, a linear actuator moves in this direction on a straightforward plane. For an operation that involves circular motion, a rotary valve is used (as with a butterfly valve).

Actuators can have manual functionality (operated by a handwheel) that happens alongside the energy-powered automatic operation. To power the actuators, there are three types of energy sources: electrical, hydraulic, and pneumatic.

3 Types of Actuators

Electrical: Components are connected to an electrical power source.

Hydraulic: Parts move with the energy of liquid force.

Pneumatic: Compressed air provides the energy source.

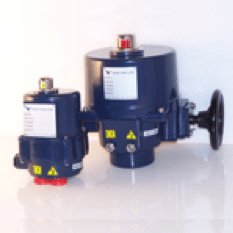

So what is an electric actuator? Among actuators, electrical is the most common type. Because of the rise of automation in technology, there’s been an increase in applications for electric actuators.

The Main Components of an Electric Actuator

An actuator is designed according to the job it needs to do. The voltage needs vary depending on the motor requirements.

Single-Phase Motor Voltage VAC Range:

- 115

- 24

- 12

- 24

- 208

- 230

Three-Phase Motor VAC Range:

- 230

- 480

Knowing the actuator components is the way to know how each type of electric actuator works.

Linear Operations

This operation is straightforward and works as a DC motor would. This process is about moving the object for a specific length along the linear plane, then with equal length for the return motion.

Positive to positive with negative to negative connections advance the shaft forward and then the opposite electrical connections bring the shaft back to its original position.

Electric motors spin, but when powering an actuator the motor moves a lead screw along with a gear system that pushes the object forward. A limit switch is set to stop the motion at a certain point. For the backward motion, there is a second limit switch that stops it at its original position. This set length of movement is called the “stroke.” The motion is like a retractable pen, where the tip extends, and then is pulled back inside.

Rotary Operations

Some actions require a cyclical motion, as with cranking. There are a variety of different ways to produce this motion and the design is dependent on the application.

Basically, this process operates on a circular plane with a gear system producing the necessary torque to create either complete or partial circular motion. This involves either constant revolutions of a spinning shaft (like a drilling motion) or moving a defined point a certain degree of a turn (like an oscillating motion).

Hybrid Operations

Both linear and rotary come together in a hybrid called a roto-linear actuator. This process is mainly driven by the linear start and stop stroke of the shaft, but then the shaft twists as the secondary motion.

Common Applications of Electric Actuators

Generally speaking, electrical actuators automate repetitive and defined tasks, as with robotics. Actuators are used with very small motions to large scale processes.

Everyday consumer-level examples of actuator applications include automatic sliding doors, adjustable seats, or windshield wipers.

For example, the EOM Series Actuator can be used for the following industrial purposes:

- HVAC

- Food Service

- Petrochemical

- OEM

- Fire Control

- Seawater

- Flue Gas

- Chemical

How Do I Select an Electric Actuator?

Since automation is about making complex processes more efficient and streamlined, a number of factors are involved when selecting the actuator that best fits the plan. Here are some general items to consider when evaluating the options.

- Speed: How fast does the actuator need to move? Critical speed calculations can be used to determine if the actuator is compatible with the application. Voltage plays an important part in speed demands.

- Load: What are the service life needs of the application? Demands will be different depending on the application. (Some examples of load factors: radial load capacity, support carriage moment capacity, axial load capacity, the actuator’s stiffness, positioning of the load, vertical vs. horizontal mechanics, nut & screw vs. rack-and-pinion.)

- Stroke length: Is the actuator equipped for the dimensions and space needed for the task?

- Repeatability: Is the operation of the actuator going to perform according to the budget and time constraints of the job? Is there a more efficient option?

- Duty cycle: Does the actuator have a reasonable chance of withstanding the demands of the job? Is there one that would perform better?

- Environment: Is the actuator appropriate for the industry and compliant with any applicable regulations? Is the task in question happening in a clean-room environment vs. a “dirty environment” involving contaminants and liquids?

- Budget: When planning for operation costs, there will be multiple line items. Where is this actuator in the rank of priorities when it comes to operational expenses?

If an appropriate electric actuator isn’t found, perhaps a hydraulic or pneumatic actuator would work as an alternative for the desired result.

Actuators Make It Automatic

In summary, actuators work to make repetitive mechanical and manual tasks automatic. In this age of automation, more and more is being done by machines. Actuator engineering is one of the ways to implement automated tasks in a variety of applications both at the consumer and industrial levels.

Butterfly Valves and Controls offers a wide selection of high quality electric actuators for a variety of applications.

No Comments