22 Jul Triple Offset vs. Double Offset Butterfly Valves: Which Is Right for Your Application? Key Differences Explained

Choosing the Right Butterfly Valve: Double Offset vs. Triple Offset

When selecting the right valve for your industrial process, understanding the difference between double offset butterfly valves and triple offset valves is critical. Each design offers unique performance characteristics suited for specific pressure ratings, media types, and temperature conditions. Whether you are engineering a chemical pipeline, refining a power plant system, or sourcing high-performance components, choosing the right butterfly valve can improve efficiency and extend service life.

This article compares both types in detail, outlines common applications, and provides a comparison chart to help you decide.

What Is a Double Offset Butterfly Valve?

A double offset butterfly valve features two distinct shaft offsets:- The shaft is placed behind the valve disc

- The shaft is offset from the centerline of the pipeline

This design allows for a cam-like motion as the valve opens and closes, minimizing wear on the seat and creating a position seated tighter shut-off compared to concentric butterfly valves. They are well-suited for applications requiring moderate pressure (to 300# ANSI) and temperature resistance to 500F Learn more about our high-performance butterfly valves for precision sealing in demanding environments.

What Is a Triple Offset Butterfly Valve?

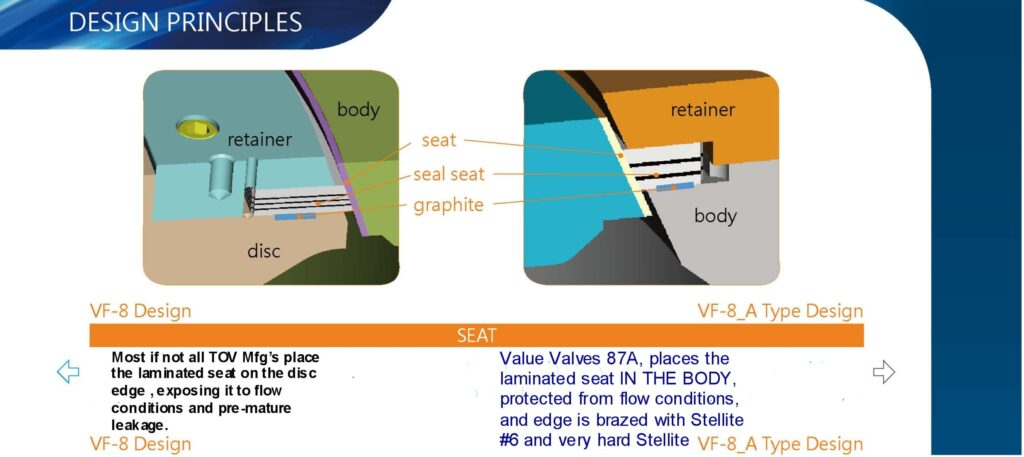

Triple offset valves take the double offset design a step further by introducing a third offset, an angular seat geometry. This allows the disc to seal against the seat with minimal friction, creating a torque-seated, metal-to-metal or graphite/metal-to-metal seal that excels under extreme conditions.

Key Benefits of Triple Offset Valves:

- Zero leakage capability

- Ideal for critical shut-off applications

- Excellent for high pressure to 900# ANSI and high temperature to 2000F

- Long service life with low seat wear

- Inherently Fire Safe with soft seat

Explore our full line of triple offset valves designed for heavy-duty industrial environments.

Applications of Double and Triple Offset Butterfly Valves

Understanding where each type of valve is commonly used can help guide your selection. Both double offset and triple offset butterfly valves offer versatile performance across industries, but their ideal use cases differ based on system demands.

Double Offset Butterfly Valve Applications

- Water treatment and distribution

- Oil and gas pipelines

- HVAC systems

- Power generation (non-critical zones)

- Marine systems

Triple Offset Valve Applications

- Refineries and petrochemical plants

- Steam and condensate systems

- Power generation (high pressure, safety-critical areas) Sil 1

- Chemical processing plants

- Offshore platforms and FPSO systems

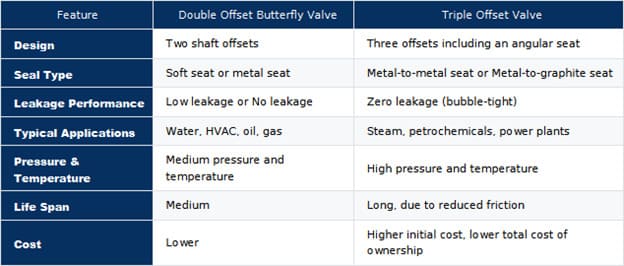

Comparison Chart: Double Offset vs. Triple Offset Butterfly Valves

Engineering Insight: Torque, Seat Design, and Leakage Classes

For engineers evaluating performance criteria, here are additional technical factors to consider:

- Torque Requirements:

Double offset valves require less torque to operate, as they are position seated with a body stop, making them a better fit for automation in lower-pressure systems or positioning/throttling. Triple offset valves require higher torque as they are torque seated but offer better sealing under stress, and increased torque, not to exceed MAST increases seating ability. - Seat Contact and Wear:

Double offset designs have contact in the last +10 degrees between the disc and the seat through part of the rotation. This causes gradual wear. Triple offset valves, with their cam-action and angular sealing geometry, have contact in last +2-3 degrees thus reducing friction to nearly zero until seating, greatly improving valve longevity. Generally, the TOV can be forced further closed for better seating adjustment over time, whereas the DOV cannot, due to the body stop. - Leakage Classes:

According to ANSI/FCI 70-2 standards, triple offset valves can meet Class VI (zero leakage) requirements using a metal-to-metal / Graphite seat. Double offset valves typically achieve Class V or VI, depending on the seat material and actuator configuration. - Fire-Safe Certification:

Triple offset butterfly valves with Metal/Graphite are API 607 fire-safe certified as standard ensuring they maintain a seal in case of fire, critical in petrochemical and offshore operations. Double offset valves must have a combination of metal and a soft seat to achieve API-607 Fire safe.

If you need assistance selecting a valve that meets your engineering specs, pressure class, or compliance requirements, explore our high-performance butterfly valves or get in touch through our contact page.

Final Thoughts

Both valve types offer reliable performance in industrial settings, but the right choice depends on your operating conditions. By understanding the difference between double offset and triple offset butterfly valves, you can make an informed decision that optimizes performance, minimizes downtime, and improves operational safety.

Explore all our industrial butterfly valves to find the solution that meets your exact specifications.

The primary advantage of a triple offset valve is its zero-leakage, metal-to-metal sealing capability, making it ideal for high-pressure, high-temperature applications.

Double offset butterfly valves are ideal for systems that require reliable sealing with moderate pressure and temperature, such as water treatment, HVAC, and oil pipelines.

Yes, triple offset valves typically have a higher upfront cost, but their longer lifespan and lower maintenance needs can make them more cost-effective in the long term.

Sorry, the comment form is closed at this time.