04 Sep Zero, Double Or Triple Offset Butterfly Valve? What’s The Difference?

Choosing the right valve is essential for a successful operation of any flow system that needs to control liquid flow. How do butterfly valves work and what differentiates them from each other you may be wondering? Each offset valve has functionality and benefits of their own. Read our blog to see which butterfly valve will aid in getting the job done!

Source: Crane Engineering

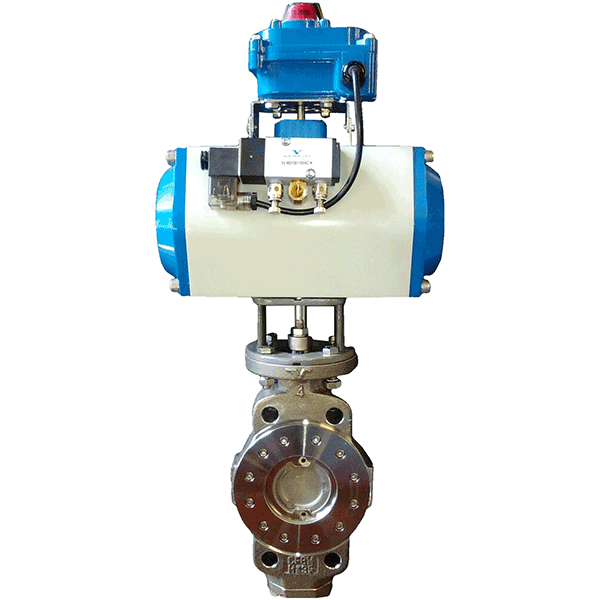

Triple Offset Butterfly Valves

Triple offset butterfly valves (TOV) have three separate offsets as shown in the picture above to the right. Two offsets are placed from the center while the third is on the seating surface which creates a cone type shape of the disc and seat. These valves are used mostly in applications where a tight bubble shut-off is required, a high temperature is expected or hard sealing surfaces are required with zero leakage(soft seat) or rated leakage(metal seat).

They are low maintenance with an extended valve life since there is no clogging or cavities between the sealing components and the disc only engages the seat in the last 1 degree. These valves are best for high-temperature gases and oils, as well as high pressure over 150 PSI or when API-607 Fire Safe is a requirement as TOV’s, are inherently Fire Safe T as well.

A triple offset butterfly valve is used in similar industries to those in which double offset valves would be used but are even more effective in demanding and tight applications. The TOV’s that offer the valve with the seat in the body vs seat on disc edge would last longer in abrasive applications. TOV with removable disc and stem without welding, (spline drive) will be more maintenance friendly.

Double Offset Butterfly Valves

This valve is also known as a high-performance butterfly valve and is quite popular since it can be used for various applications. This valve has two offsets from the center which creates a cam action during the application process. Double offset butterfly valves are best used for:

- Oil and gas

- Pulp and paper

- Power generation

- HVAC

- Chemical

- Shipbuilding

- Water/wastewater treatment

These valves are used for higher pressure than zero offset butterfly valves (ANSI Rated), and offer adjustable packing on the stem thus lower emissions and stem leakage.

Zero Offset Butterfly Valves “Concentric Design”

Zero offset butterfly valves are used for liquid and gas applications up to 400 degrees Fahrenheit and 250 PSI. The stem and disc of these valves are centered in the valve seat which is centered in the body of the valve. This valve can handle chemicals, coatings, food, some solids, and abrasive applications. An advantage of using a zero offset valve is that the media going through the valve will not contact the body since the seat of the valve covers the body.

Choosing the right valve for your operation can be a tough decision. Before making your purchase, contact our team of specialists at Butterfly Valves and Controls to help you find the valve that best suits your needs.

Sorry, the comment form is closed at this time.