17 Oct What makes a GREAT High-Performance or Triple Offset Butterfly Valve

It’s important to select the right tool for your flow system. Controlling liquid flow is a critical task that can be accomplished by a great high-performance or triple offset butterfly valve. However, what actually makes a good offset valve? Each offset valve has its own functionality and set of benefits. Below, we’ll talk about what to look for to select the best tool for getting your job done right.

What characteristics make a high-performance butterfly valve/triple offset butterfly valve?

Let’s discuss the characteristics of high-performance butterfly valves and triple offset butterfly valves. The first question to answer is the simplest: what is one of these valves anyway?

Triple offset butterfly valves were introduced more than 50 years ago, but their use has evolved and changed with time. The original objective was to ensure shut-off in water, oil and other typical applications. The improvements in their design over the years has made the tool especially valuable.

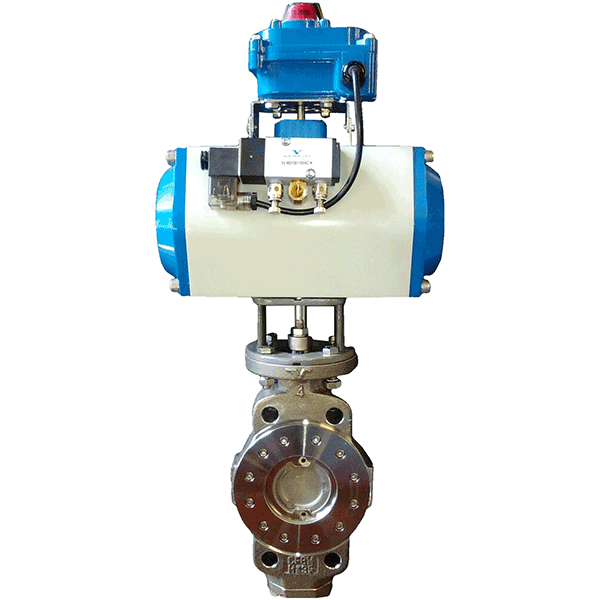

High-performance butterfly valves contain a disc offset from its seat’s center, which is why offset is in its name. With this class of valve, the disc is offset relative to the valve seat. This means that as the disc moves, it navigates away from the seat rather than directly across it. When this occurs, the resulting line pressure gives the valve its seal. For this reason, an offset butterfly valve is often used for ethanol and HVAC systems, where high pressure is a concern. It is often likely to use cheaper seat parts such as plastics as opposed to metal. However, some metal seats do exist on offset valves, for instance when fire hazard is a concern.

What makes the triple offset valve different?

A triple offset valve, or TOV, actually has a different make-up than double offset alternatives. It contains a torque-seated valve instead and boasts seats usually composed of metal or harder materials. But that’s not all that distinguishes this class from the double offset valve. The TOV also has, suitably, three offsets. Unlike a standard butterfly valve, a TOV contains a disc torqued into its round seat. The set up is designed to eliminate all leakage with its cone-shaped disc. These are widely available and often measure up to 13 to 14 feet. These are also made to withstand various environments.

Triple offsets are useful across industries and provide similar use to double offset valves. The difference being that TOVs are better suited for especially tight situations. It can also withstand tougher applications when the seat is positioned in the body rather than at the edge of the disc. Certain kinds of TOVs, such as those that are easily disassembled, make for easier long-term maintenance.

Triple offset butterfly valves provide a cost-saving advantage and optimal torque transmissions, sealing performance, and resilience in the face of high temperatures, especially compared to traditional butterfly valve designs. The fire safe designs increase the range of possible applications as well. Ultimately, you will have to decide what tool works best for your application based on the specifics. There is a triple offset butterfly valve out there for many applications, it’s all a matter of finding the right fit.

Sorry, the comment form is closed at this time.