02 Mar Triple Offset High Performance

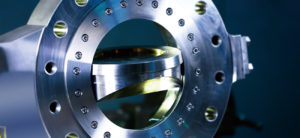

High Performance Triple Offset Butterfly Valve

Triple Offset High Performance

DESCRIPTION

General

- Size: 3”~108”(80 mm ~2700mm)

- Temperature Range: -320F-1022F (-196C- 550C)

- Pressure Rating: ANSI 150/300/600/900 ANSI

Design: To meet the customer requirements in flow control systems, Value Valve is constantly developing our products to be a superior product choice in sever applications. Value Valve created a new unique design for a High Performance Triple Offset Butterfly Valve by improving the materials as well as the mounting structure

Value Valve is one of the few companies that has been certified with the Safety Integrity Level 3 according to IEC 61508-1 and ISO 9001 by TUV for the VF-8 series.

Features:

Value Valves VF-8 Series features a One Piece Removable/Repairable Shaft and Disc with Internal Spline Drive allowing the removal of Seat, Disc and Stem for inspection and ease of maintenance

The SEAT of the VF-8 Series Triple-Offset butterfly valve is available with Graphite Laminated Seat or Solid Metal Seat.

Graphite Laminated seat is Bubble Tight and “Fire Safe”. The Stellite 21 “Seat -in- the-Body” design provides significant increase in service life compared to seat on disc edge (which is exposed to whatever the pipeline media may be.)

Stellite 21 harden Disc Edge overlay increases hardness of sealing surface and provides long service life.

Life Cycle – 50,000 cycles with out adjustment

The Value Valve Triple Offset Butterfly MOUNTING valve is TRUE ISO-5211 Mounting for easy automation utilizing anyone’s ISO-5211 actuator. The Pad is ISO-5211 and the STEM is ISO-5211.

The Value Valve VF-8 is rated Sil-3

Why SELECT SIL-3 Valves/ Actuators?

SIL stands for Safety Integrity Level. A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) There are four discrete integrity levels associated with SIL: SIL 1, SIL 2, SIL 3, and SIL 4. The higher the SIL level, the higher the associated safety level, and the lower probability that a system will fail to perform properly. For the process industries, SIL 4 systems are so complex and costly that they are not economically beneficial to implement.

Selecting the appropriate SIL level must be done carefully. Costs can increase considerably to achieve higher SIL levels. Typically, in the process industry, companies accept a SIL 2 rating, but if you can obtain a Butterfly Valve or Automated Butterfly Valve Package with a complete Standard SIL-3 rating, utilizing our RP series actuator with little or no increase in cost, then that is the logical decision.

| Safety Integrity Level | Risk Reduction Factor | Probability of Failure on Demand |

| SIL 4 | 100,000 to 10,000 | 10-5 to 10-4 |

| SIL 3 | 10,000 to 1,000 | 10-4 to 10-3 |

| SIL 2 | 1,000 to 100 | 10-3 to 10-2 |

| SIL 1 | 100 to 10 | 10-2 to 10-1 |

You can see a SIL-2 valve/actuator is 10X more likely to fail than a SIL-3

Specifications:

Body Style: Wafer, Lug, Double Flange Type

ANSI Class 150,300,600 and 900

Body Shell Thickness: ASME B16.34

Mounting: ISO 5211 Pad and Stem

Design & Pressure: ASME B16.34

Face to Face: API 609, ISO 5752

Inspection and Testing: ISO 5208, API 598

Fire Safe: API 607, ISO 10497

VOC: ANSI/ISA-SP-93, TA-Luft, ISO15848-1/-2

Cryogenic: BS 6364

Standard Marketing System: MSS-SP-25

EX Certificate: ATEX

Safety Integrity Level 3 (SIL3): IEC-61508-1

Leakage Class: ANSI FCI 70-2-2006 TABLE 1, ISO 5208

Flange Connection: ASME B16.5 Class 150/300/600/900LB, ASME B16.47 Class 150/300/600/900LB

(Other flange connection please contact BVC

*Technical information is only for reference. Subject to change without previous notice..)

More information: High performance butterfly valves

Sorry, the comment form is closed at this time.