02 Apr High-Performance Butterfly Valves

High-Performance Butterfly Valves

High-performance butterfly valves have a different structure than that of general use butterfly valves. Referred to as double offset butterfly valves, high-performance butterfly valves have a disc that is offset from its seat center, which is referred to as eccentric. The unique characteristics of these high-performance valves necessitates that they be manufactured using the highest quality materials in order to withstand the temperatures and stress related to their use. As a leader in the manufacture of butterfly valves, Butterfly Valves & Controls offers high-performance butterfly valves capable of withstanding pressure up to 1440 psi at temperatures as high as 1200o F.

The typical butterfly valve functions by turning a handle that rotates the stem and disc of the valve. This simple opening and closing function is a critical part of controlling the flow of liquids, gases, and slurries. The importance of the work of butterfly valves necessitates that they have the endurance, strength, and dependability required for critical manufacturing applications. An unfortunate aspect of general butterfly valves is the inability of their elastomers to withstand erosion, when minute particles of a butterfly valve seat crack off.

A typical butterfly valve consists of a body, disc, stem, and supporting components. The disc is rotated 90o to stop or allow the passage of gases and liquids. As beneficial and valuable as typical butterfly valves may be, there are applications that they are unable to handle, which has led to the development by Butterfly Valves & Controls of high-performance butterfly valves.

High-Performance Butterfly Valves (HPBFV)

The unique double offset disc construction of Butterfly Valves & Controls high-performance butterfly valves allows for bi-directional sealing throughout the full pressure range of the valve. Included in their design are resilient and durable materials, such as Teflon/Graphite, that enables the valves to withstand the reactivity of chemicals and the corrosive effects of liquids, gases, and steam.

The demanding nature of the work performed by high-performance butterfly valves requires that they be constructed of the strongest, most resilient, and longest lasting materials. High-performance butterfly valves from Butterfly Valves & Controls are made from a variety of exceptionally durable metals including high quality carbon steel and stainless steel. The selection of metal is dependent on the application for which a high-performance butterfly valve will be used.

The seats for Butterfly Valves & Controls high-performance butterfly valves are made of polytetrafluorethylene (PTFE) due to its ability to prevent leaks, its reliability, and its stability in the harshest conditions. The double offset stem of the valve is placed behind the disc to create a cam action, a design that increases wear resistance. In addition, sealing, provided by PTFE, provides tight shutoff in high-pressure and high-temperature applications.

Some of the applications for which high-performance butterfly valves are used:

- Oil and Gas: High-performance butterfly valves control high-temperature and high-pressure fluids that are common part of oil and gas processing.

- Chemical Processing: The processing of chemicals involves the use of toxic, corrosive, and volatile chemicals that Butterfly Valves & Controls’ high-performance butterfly valves are designed to control.

- Power Generation: Power plants necessitate precision control of the flow of steam. High-performance butterfly valves are able to direct and control steam flow safely with precision.

- Food and Beverage: The Food and Drug Administration (FDA) has strict standards regarding any materials that make contact with food products. The high quality of the sealing material of Butterfly Valves & Controls’ valves makes the company’s high-performance butterfly valves ideal for use by the food and beverage industry.

- Pharmaceutical: High-pressure butterfly valves are a necessity for the pharmaceutical industry due to the chemicals involved in the production of pharmaceutical products.

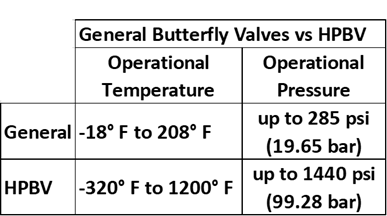

A comparison of general butterfly valves and high-performance butterfly valve highlights the reasons that there is such a demand for high-performance butterfly valves. The superior characteristics and properties of Butterfly Valves & Controls’ high-performance butterfly valves has made them an essential part of demanding industrial processes. The close attention to precision, design, and performance by the engineers at Butterfly Valves & Controls is one of the reasons that the company’s high performance butterfly valves are in such demand.

Double and Triple Offset High-Performance Butterfly Valves

The two configurations of Butterfly Valves & Controls’ high-performance butterfly valves are double and triple offset. The functions of both types of offsets are the same but performed in different ways. The factor that differentiates the two types of high-performance butterfly valves is their number of offsets and the seat configuration. Double offset high-performance butterfly valves have two offsets while triple offset butterfly valves have two offsets and a seat offset.

- Double Offset High-Performance Butterfly Valves

The unique aspect of double offset high-performance butterfly valves is their cam action. The first offset is a position shaft placed behind the valve disk. The second offset is placed behind the valve to one side of pipe center. The cam action of the discs limits their contact with the disc seat, which increases the life of a high-performance butterfly valve. The arrangement and positioning of the discs off the center of the pipe bore adds to the durability of the valve’s sealing function.

In addition, the positioning of the discs for Butterfly Valves & Controls’ double offset high-performance butterfly valves enables the valves to endure the high-pressure generated by stressful applications. The sizes of double high-performance butterfly valves range from 2 inches to 48 inches with heat tolerances of -21o F up to 932o F and an ANSI pressure rating of 150 psi or 300 psi.

- Triple Offset High-Performance Butterfly Valve

The design of triple offset high-performance butterfly valves is similar to that of double offset high-performance butterfly valves. They have two offsets positioned in the same manner as double offset high-performance butterfly valves. The third offset has a cone axis that deviates from the axle centerline, a position that eliminates friction through the use of contact pressure.

A distinguishing feature of triple offset high-performance butterfly valves is their ability to deal with dirty fluids due to their tolerance of dirt. They are manufactured to endure the most hostile environments and are often used for high-pressure steam operations and oil, gas, and chemical production. Their heat tolerance is from -320o F up to 1022o F with ANSI pressure ratings of 150, 300, 600, or 900 psi.

As with double offset high-performance butterfly valves, triple high-performance butterfly valves extend the valve life. They allow for uniform sealing with a tight shutoff metal seat design, which is lower cost and lower torque than other metal seated valves. The unique design of triple offset high-performance butterfly valves allows them to handle higher pressures with lower emissions. They are built to endure and withstand a wide variety of environments and conditions.

| Feature | Double Offset | Triple Offset |

| Seal Type | Reduces Friction Uses Teflon Deformation for Sealing Soft Materials Used for Valve Seats and /or Metal to Metal API-607 Fire Safe ISO-5211 Standard Mounting | Laminated Graphite / Stellite Metal-to-Metal Seal |

| Fluid Types | Clean Fluids, only | Effective with Dirty Fluids |

| Applications | Water Treatment Chemical Production Oil Refining Gas Refining HVAC Systems API-607 Fire Safe Standard ISO-5211 Standard Mounting | Industrial Applications with Higher Temperatures and Pressures |

Conclusion

Butterfly Valves & Controls’ high-performance butterfly valves are able to endure exposure to extreme and hazardous conditions. Our double offset butterfly valves have reinforced splined shafts for increased strength and ease of maintenance as well as blowout protection. They provide bi-directional shut-off with seats made of Stellite or reinforced Teflon to endure high pressure and temperatures.

Our triple offset butterfly valves are also bi-directional with laminated multilayer seats made of Stellite and graphite or solid Meat seats They are manufactured for extreme application environments

The quality of the products produced by Butterfly Valves & Controls has been recognized by industry leaders who depend on our dedication and precision to supply durable butterfly valves. The many services we provide has made us an industrial leader. We look forward to providing you technical support and guidance.

Sorry, the comment form is closed at this time.