11 Feb Anatomy of A High Performance, Double Offset, Butterfly Valve

High-performance butterfly valves are an essential component for any company that needs to control the flow of gases or liquids. Although butterfly valves have been used since the early 1930s, their use as an effective, low maintenance mechanism to regulate fluid flow has only recently become popular in industrial settings. This popularity can be attributed to its tight shutoff ability, ease of operational use, and availability in a number of materials.

Although the design of the butterfly valve appears simple, it is still important to understand its mechanism in order to properly integrate it into your pipe system and other fluid-control mechanisms. Here are the four key components and functions of high-performance butterfly valves.

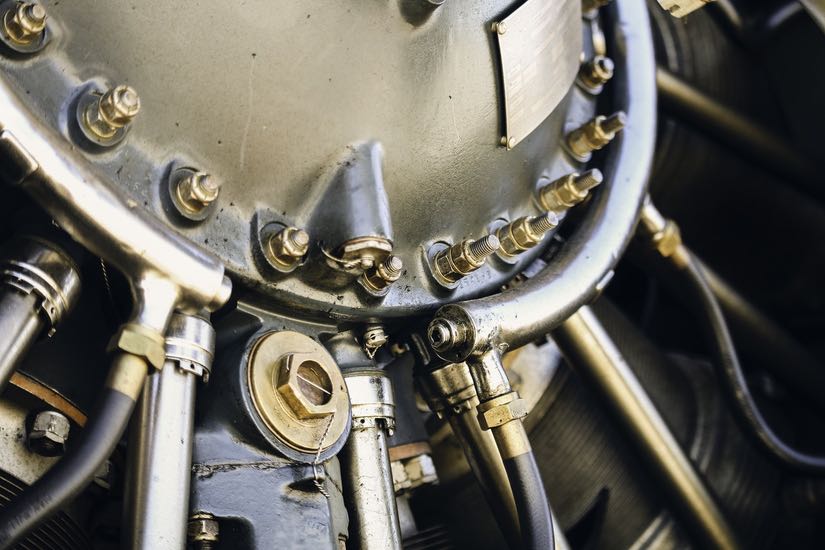

Rotating Disk and Stem

The disk component is the most important part of the butterfly valve as it is what ultimately regulates fluid flow. The spherical disk contains a stem, which is a metal rod running through the circular disk. When the stem is rotated one-quarter turn (ninety degrees), the disk opens or closes. Many improvements to the disk have been made since butterfly valves were first invented to control both the level of torque and the sealing ability of butterfly valve disks. Typically, the stem and disk are centered in the seat and pinned together and the spot welded. More recent innovations attach the stem to the disk via splines on the OD of the shaft that match splines inside the disk. This feature gives you the benefit of being able to remove the seat AND the shaft and disc for repair and/or inspection. It also gives you a stronger connection as the two have not been drilled and welded at high temperatures.

Body

The body of a butterfly valve is the component placed between two pipes, allowing media to flow through the butterfly valve. There are two common body types for butterfly valves: the wafer type and the lug type. The wafer body type is less complex as it simply connects by fitting between two pipe flanges with through bolts that go from flange to flange. The lug body type is slightly more complicated as it is held between two flanges by opposing bolts that run through both flanges and the valve’s outer casing. The simplicity of the wafer body type makes it more economical, but the lug body type allows different services to be performed such as dead-end service for removal of downstream piping.

Seat

The seat component of the butterfly valve is what allows the disk to seal in place, preventing the flow of any media. Utilizing an interference fit between the disk edge and the seat itself is what allows this seal to form. This point of contact is exposed to the media and sometimes high velocities as it closes, so treating the disk edge via hardening or hard chrome plating extends the life of the disk and seat.

High-performance butterfly valves utilize several materials to form the seat including different polymers and elastomers. Some of these materials are polytetrafluoroethylene (PTFE)with a bubble-tight shutoff, metal seats such as Inconel, with a rated leakage, or a combination metal and PTFE seat making them “Fire Safe” allowing butterfly valves to be used at temperatures as high as 1000 degrees Fahrenheit.

Choosing the right valve to control the flow of media is important for many industries. Remember that both the mechanism and structure of the valve must be carefully evaluated. By knowing these four major components, your team will be better able to select the right butterfly valve for any application. If you have any questions give us a call.

Sorry, the comment form is closed at this time.